When we say that “manufacturer is investing in injection molding machine” we are refering that the manufacturer’s high stakes are at risk now and if the machine is too big for his need to to be small then unfortunately this can cause trouble soon. It is very important for the manufacturer to know what he is going to do while selecting the machine for his needs. So, in this guide, we are going to discuss features like which machine type he should use, what should be the clamping force, etc.

In the vast sea of injection molding machines available, it's easy to simplify the decision-making process by considering only the machine's simplicity and clamping force. However, a nuanced approach is important and in this regard the weight of injection would be more critical parameter.

Expressed in grams or ounces, injection weight signifies the maximum plastic injection weight achievable during the injection process. It may seem straightforward, but nuances exist. So, it should be taken into consideration that injection weight is not only the ratio of length and volume and density of the material but it is actually a complex calculation of other factors like product weight, plastic or material type and gate system.

Selecting the right injection molding machine is a critical task, and a key factor in this decision-making process is determining the injection weight. This involves a critical procedure that requires the reviewing of production requirements, efficiency and minimizing waste. Later in this article, we are going to discuss it step by step.

The first and foremost step is to calculate the weight. Which requires adding the weight of the actual product and the weight of gate system. The formula that can be used is as:

Formula: W = Product Weight + Gate System Weight

For products molded in polystyrene (PS), the next step is to determine the injection volume of the machine. So, this can be achieved when we multiply the coefficient whose value is from 1.3 to 1.1 by the weight of the product. The coefficient can be chosen by taking into consideration the product requirement.

Formula: Wps = Coefficient × W (Product Weight + Gate System Weight)

The Wps represents the volume of products (the PS product) and coefficient can be adjusted by the requirements of product like the size, shape etc.

If the product is molded using plastics other than PS (referred to as X plastic), the process involves calculating the theoretical injection volume (Wx) first. Like the previous step, this is done by multiplying the calculated product weight (W) by a coefficient ranging from 1.3 to 1.1.

Formula: Wx = Coefficient × (Product Weight + Gate System Weight)

Once the theoretical injection volume is determined, it needs to be converted to the actual weight of PS material (Wps) using a density conversion formula. This formula considers the density (Vx) of the specific plastic material being used.

Formula: Wps = Wx × 1.05 / Vx

By using this formula we make sure that weight is correct according to the chosen plastic. It is an important step for precision in the molding process.

The clamping force of an injection molding machine is a pivotal factor in ensuring proper mold closure during the injection process. It incorporates two components the cavity pressure and the projected area. The projected area would be the largest area that is visible while the cavity pressure is influenced by factors.

Finding the cavity pressure includes thermoplastic flow characteristics, assigning viscosity grades, and calculating a multiplication constant (K). The clamping force (F) is then determined by the formula: F = P0 × K × S.

However, this step includes the machine’s ability to hold the mold, prevent defects and maintain product quality.

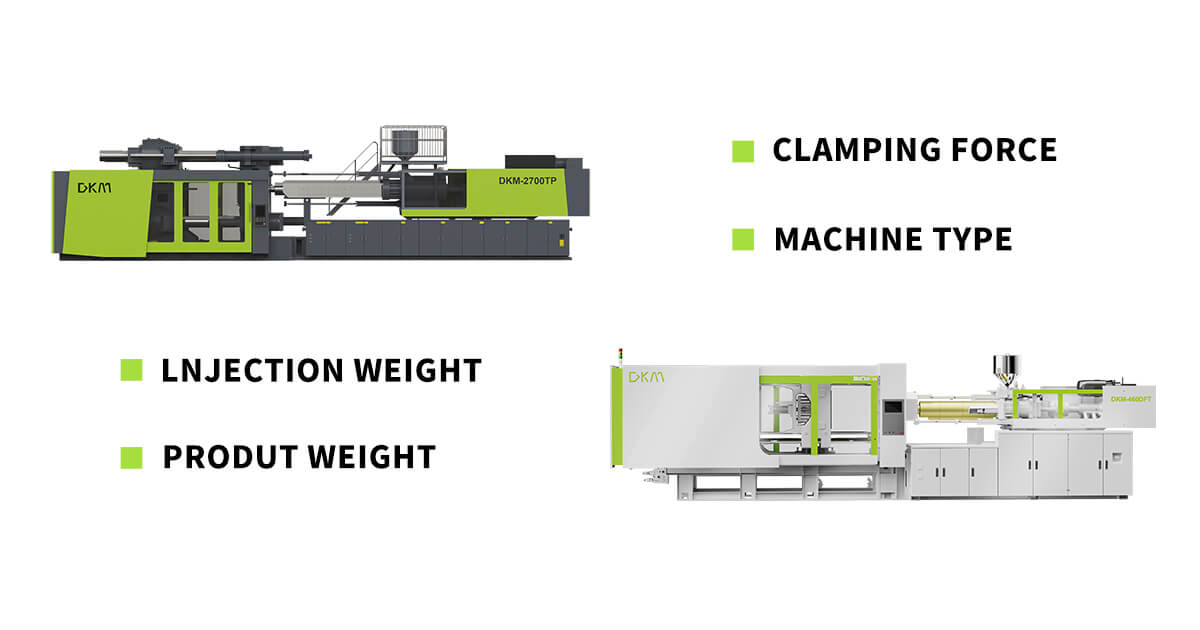

Choosing the right type of injection molding machine is crucial for optimizing production efficiency. Three main types are prevalent in the market:

Historically dominant, hydraulic machines have been the go-to option for molders. Except in Japan hydraulic machines are widely used globally.

Due to reduced operations cost and consumption and multiple other factors, the Electric machine technology was introduced in 1983, they gained popularity as they offer higher accuracy, speed, and lower noise levels but come with a higher initial cost.

This system claims to have the best-combined features of both hydraulic and electric systems. Also known as "Servo-Hydraulic" machines. But instead of these features, these machines use a lot of electricity, depending on the manufacturer.

By knowing these kinds of migor details and features of multiple machines it become an informed decision for the manufacturers whether they need them or not. Or in which thing they are investing.

Due to the chain and cost advantages the Chinese manufacturers gained extreme popularity. But let us tell you one thing, choosing the right manufacturer is as important as choosing the right machine. So, to facilitate this procedure for you here we are mentioning the platforms that you can use.

1. DKM: For exporting quality products in different regions it is considered as China’s largest platform.

2. Made in China: This platform features Chinese suppliers and promotes Chinese products.

3. Global Sources: They provide professional services for small and medium-sized enterprises, providing professional services for foreign buyers.

Searching through Google for brand manufacturer websites can yield professional and responsive options, typically offering quicker and more personalized responses than B2B platforms.

· As we have discussed above reviewing the features is not enough but having an eye on the manufacturer is also very important. So for this follow the following step to avoid any future problems.

· The step one is to review the feedback, and reviews of previous customers.

· The second thing to consider is to know about the company. Its mission vision and everything.

· The next what you can do is initiate a conversation with your manufacturer on a personal level. This will help you to know their professionalism etc.

Purchasing a plastic injection molding machine is a substantial investment, and the decisions made during the selection process can significantly impact a business's success. By following the above mentioned steps in choosing the machine features for the manufacturers can help a lot.we