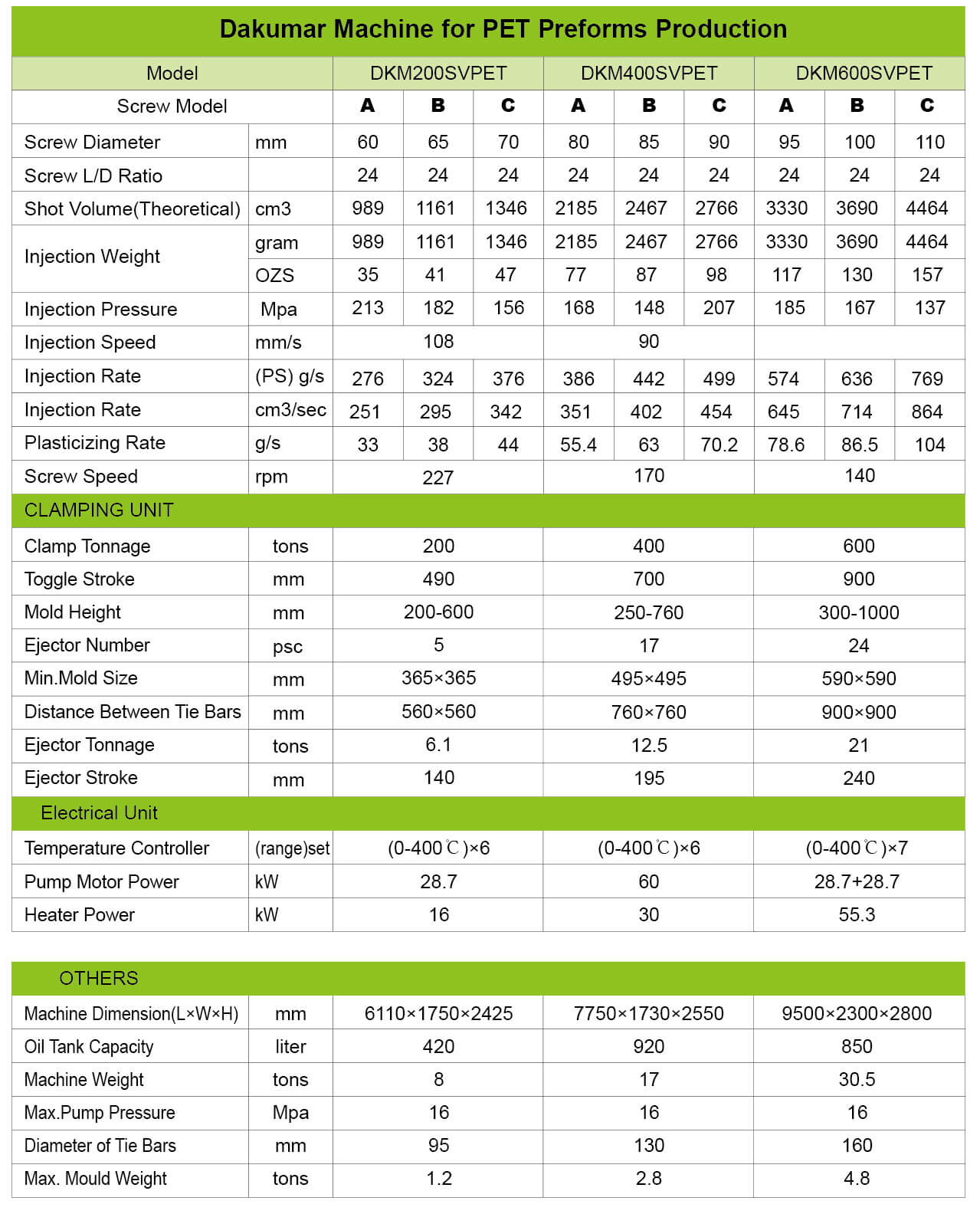

Injection Molding Machine

DAKUMAR, as the professional PET bottles production line supplier in world, try to develop high efficiency and high energy saving PET preform molding and blowing machines to our customers and the specially designed PET preform injection molding machines is one of the most important improvements.

With the development of PET bottles packaging industry, PET preforms and PET bottles production are in hot market. DAKUMAR, as the professional PET bottles production line supplier in world, try to develop high efficiency and high energy saving PET preform molding and blowing machines to our customers and the specially designed PET preform injection molding machines is one of the most important improvements.

DAKUMAR PET preform injection molding machine are with below advantages: