企业博客

一、注塑机的起吊拆装

小机是整体式,不需拆装,在起吊时,调模应调到最小模厚。

大机拆装将由注塑机厂家大机组人员完成如果机器在厂房内再次移动且没有吊机时,需要在机器底部垫上滚木。由于机器较重,应由有起重经验的起重工来指挥,要注意下列各项:

(1)使用足够强大的提升机和搬运机将机器提起。

(2)如果任何吊挂钢丝绳与机器接触时,要在钢丝绳与机器之间放入布层或木块以避免损伤机器的零件,如注塑机的拉杆等。

(3)木块垫块或垫件在机器下卸和搬运全部完成后才能移掉。

二、防锈

所有暴露在空气中的机械部分,如活塞柱、拉杆以及模板部分的加工表面,在出厂前都涂过防锈剂。轴承表面润滑油和干净液压油的混合油可以产生一层防锈薄膜。

在操作不与机器接触的部分,涂上防锈剂,为机器提供了抵抗腐蚀和恶劣环境的保护。除非确实需要,运行时再擦去防锈剂,但禁用溶剂擦去防锈剂。

三、安装环境

温度:0~40℃(运转时的周围环境温度);湿度:75%以下(相对湿度),不得有结露。

海拔高度:海拔1000米以下。当湿度太高时,会使绝缘状态不佳,零件提前老化,勿将注塑机安装在多湿的环境中。也不要安装在灰尘多的场所或有机性瓦斯、腐蚀性气体浓度高的场所,要远离会发生电气干扰或具有磁场的如焊接机等机械。

四、电源连接电力电缆到电气箱中的电源进线,为三相五线,电压为380V,频率为50Hz。

五、开机调整参数

六、试模,打出产品

联系人:小王

一、注塑机的起吊拆装

小机是整体式,不需拆装,在起吊时,调模应调到最小模厚。

大机拆装将由注塑机厂家大机组人员完成如果机器在厂房内再次移动且没有吊机时,需要在机器底部垫上滚木。由于机器较重,应由有起重经验的起重工来指挥,要注意下列各项:

(1)使用足够强大的提升机和搬运机将机器提起。

(2)如果任何吊挂钢丝绳与机器接触时,要在钢丝绳与机器之间放入布层或木块以避免损伤机器的零件,如注塑机的拉杆等。

(3)木块垫块或垫件在机器下卸和搬运全部完成后才能移掉。

二、防锈

所有暴露在空气中的机械部分,如活塞柱、拉杆以及模板部分的加工表面,在出厂前都涂过防锈剂。轴承表面润滑油和干净液压油的混合油可以产生一层防锈薄膜。

在操作不与机器接触的部分,涂上防锈剂,为机器提供了抵抗腐蚀和恶劣环境的保护。除非确实需要,运行时再擦去防锈剂,但禁用溶剂擦去防锈剂。

三、安装环境

温度:0~40℃(运转时的周围环境温度);湿度:75%以下(相对湿度),不得有结露。

海拔高度:海拔1000米以下。当湿度太高时,会使绝缘状态不佳,零件提前老化,勿将注塑机安装在多湿的环境中。也不要安装在灰尘多的场所或有机性瓦斯、腐蚀性气体浓度高的场所,要远离会发生电气干扰或具有磁场的如焊接机等机械。

四、电源连接电力电缆到电气箱中的电源进线,为三相五线,电压为380V,频率为50Hz。

五、开机调整参数

六、试模,打出产品

联系人:小王

一、注塑机的起吊拆装

小机是整体式,不需拆装,在起吊时,调模应调到最小模厚。

大机拆装将由注塑机厂家大机组人员完成如果机器在厂房内再次移动且没有吊机时,需要在机器底部垫上滚木。由于机器较重,应由有起重经验的起重工来指挥,要注意下列各项:

(1)使用足够强大的提升机和搬运机将机器提起。

(2)如果任何吊挂钢丝绳与机器接触时,要在钢丝绳与机器之间放入布层或木块以避免损伤机器的零件,如注塑机的拉杆等。

(3)木块垫块或垫件在机器下卸和搬运全部完成后才能移掉。

二、防锈

所有暴露在空气中的机械部分,如活塞柱、拉杆以及模板部分的加工表面,在出厂前都涂过防锈剂。轴承表面润滑油和干净液压油的混合油可以产生一层防锈薄膜。

在操作不与机器接触的部分,涂上防锈剂,为机器提供了抵抗腐蚀和恶劣环境的保护。除非确实需要,运行时再擦去防锈剂,但禁用溶剂擦去防锈剂。

三、安装环境

温度:0~40℃(运转时的周围环境温度);湿度:75%以下(相对湿度),不得有结露。

海拔高度:海拔1000米以下。当湿度太高时,会使绝缘状态不佳,零件提前老化,勿将注塑机安装在多湿的环境中。也不要安装在灰尘多的场所或有机性瓦斯、腐蚀性气体浓度高的场所,要远离会发生电气干扰或具有磁场的如焊接机等机械。

四、电源连接电力电缆到电气箱中的电源进线,为三相五线,电压为380V,频率为50Hz。

五、开机调整参数

六、试模,打出产品

联系人:小王

如果你正要计划投资于油漆桶注塑模具和注塑机的新项目。那么找我们就对了。我们是为客户提供桶类注塑模具交钥匙工程的专家。

油漆桶生产线——交钥匙工程。

1. 5L,10L 20L等油漆桶。我们的建议使用DKM268T,DKM520T或DKM650T,如果您的油漆桶需要膜内贴IML,在使用SINO-IML油漆桶注塑模具的情况下,配合Dakumar

及IML机器人贴标系统,机械手取件。您将得会到一个最快最稳定的全自动油漆桶生产线。

2. Dakumar是一个高性能的伺服动态控制机。双缸注塑设计结构,使得螺杆座进座退时注塑更加平稳,使用寿命更长。高度优化的机械性架构配合奥地利科霸高性能控制器,有效提升注塑机使用寿命与注塑精度。

3. Dakumar油漆桶生产线辅助机器有:全自动上料机、料斗干燥机、冷水机、空气压缩机、物料粉碎机、拌料混色机,IML机器人贴标系统。

4. Dakumar油漆桶生产线——交钥匙工程服务将为您24小时巡航保证油漆桶/涂料桶产品高效率的生产并将每一个油漆桶/涂料桶产品单位的能耗降到最低。

如果您对油漆桶生产线的项目有计划,或者你想投资成立一个生产桶产品的新工厂。欢迎前来与我联系,了解更信息。

联系人:张先生

联系电话:13666889603 0576-81107156

企业QQ:2100815886

E-mail:xiaoshou005@sinogroupe.com

继2016年德库玛全面优化了注塑机配置,以更先进的设计理念,更可靠的硬件配置,在提升产品注塑精度的同时,使节能效率达到最佳,是全球中高端注塑机用户的最佳选择。

德库玛全新升级伺服注塑机,采用优化合模单元,架构排布精密,运行平稳可靠,节能高效,适用于各种高精密度的塑料制品成型加工与生产。

伺服节能注塑机,高节能:高度优化的伺服节能技术,生产效率更高,产品单位能耗更低。高精密:高度优化的机械性架构配合奥地利科霸高性能控制器,有效提升注塑机使用寿命与注塑精度。高效率:高度优化的合模单元,高速开合模更加稳定,有效缩短循环周期。高安全:符合国家最新的安全标准:GB22530-2008 更加安全可靠。高稳定:双缸注塑设计结构,使得螺杆座进座退时注塑更加平稳,使用寿命更长。

注塑机结构经过有限元分析软件优化设计,使得注塑机架构满足高刚性,高强度,满足快速高效冲击生产需求。其中DAKUMAR固定模板:经过有限元分析,模板应力表面分布均匀,变形减小,有效的提高塑料制品的精度。优化设计后的锁模机构:采用压中心模板结构设计。注塑机锁模力直接作用在注塑模具上,模具型腔尺寸变形减少,大大提高塑料制品成型精度。

德库玛DAKUMAR追求卓越品质,创造世界品牌。

联系电话:0576-81107156 13666889603

联系人:张先生

E-mail:xiaoshou005@sinogroupe.com

①、设备的安装

安装机器的地方应放置于通风、干燥、无尘,并有足够操作空间的地方,以保证能在设备周围进行安装、调试、维修,同时应保证操作人员可方便地进行巡视,取制品,运输制品。安装该设备的地方应留有足够空间。

②、设备的调试

机器在出厂前已调好,安装后主要对以下项目进行调校:机架上平面的水平调整,纵向允许公差0.20mm/m,横向上允许公差0.16mm/m(由防震垫脚来调整)。射嘴中心度的调整(由射台螺栓调整)。

③、试机前的准备工作

机器运行之前,有必要给出厂前已加过润滑油的部位再补充一次。对于具有集中润滑系统的设备,在供润滑油之前应检查存放于润滑泵中的油存放量,如润滑油量不足,应加到量。

开机运行后要再次检查油位,如不足要再次加油,为保证设备运行良好,所加油要过滤后才可加入油箱中,可通过空气滤清器或滤油车加入,并且不同产品型号的液压油不可混用,这样会使全部液压油变质。

④. 试机

三相电源的接线应使电动机带动油泵向正确方向转动。(请注意:一定要往液压系统的油箱注够适用的液压油后,才能启动油泵)。

①、设备的安装

安装注塑机的地方应放置于通风、干燥、无尘,并有足够操作空间的地方,以保证能在设备周围进行安装、调试、维修,同时应保证操作人员可方便地进行巡视,取制品,运输制品。安装该设备的地方应留有足够空间。

②、设备的调试

注塑机在出厂前已调好,安装后主要对以下项目进行调校:机架上平面的水平调整,纵向允许公差0.20mm/m,横向上允许公差0.16mm/m(由防震垫脚来调整)。射嘴中心度的调整(由射台螺栓调整)。

③、试机前的准备工作

注塑机运行之前,有必要给出厂前已加过润滑油的部位再补充一次。对于具有集中润滑系统的设备,在供润滑油之前应检查存放于润滑泵中的油存放量,如润滑油量不足,应加到量。

开机运行后要再次检查油位,如不足要再次加油,为保证设备运行良好,所加油要过滤后才可加入油箱中,可通过空气滤清器或滤油车加入,并且不同产品型号的液压油不可混用,这样会使全部液压油变质。

④. 试机

三相电源的接线应使电动机带动油泵向正确方向转动。(请注意:一定要往液压系统的油箱注够适用的液压油后,才能启动油泵)。

联系人:小王

联系电话:15867006016

联系QQ:2954127302

注塑机能够完成注塑作业,但是在工作人员使用的时候,也应该注意到以下几点内容,这样才可保证生产过程的安全以及人身安全。

如果注塑机的温度不断升高的话,那么这种情况下给我们产生的危害还是很严重的。比如说它能够给让机器发生变形的问题。因为液压部位系统其热胀系数如果不同的话,那么它的间隙也会相应的产生变化,这样会有操作系统动作失灵的可能,而且液压系统自身传动的精准度自然也会受到影响,机器的工作质量下降。

温度升高会让油的粘度发生下降。如果出现这样一种情况,那么它会让注塑机所有系统功能都会发生下降。因为粘度下降,那么润滑部位的零部件磨损度也会大大增加,让磨损出现加剧的问题。温度过高让橡胶结构的部位件受损。因为如果温度太高的话,那么橡胶的老化速度回加快,这样它的密封性能降低,使用寿命也会降低,泄露事故发生。温度过高,也可能是因为管道发生了堵塞造成的,比如说会有过滤网的堵塞以及冷却塔的堵塞等等。

温度过高所带来的问题很多。所以工作人员在进行处理的时候一定要规避这种问题,如有发生应该及时处理。而在大家平时操作机器也需要注意不可对各种安全装置进行拆除,如果安全设施有任何错误或者是意外,都需要将机器进行关闭,在对注塑机重启之前,一定要保证故障已经被排除才行。

有更多注塑机问题可以随时联系我 --西诺罗健 email:3191@sinogroupe.com

注塑机操作是一项安全性需要比较高的岗位,如果操作不当容易造成模具损坏或者机器故障,严重的还可能造成人身伤害,DKM注塑机作为注塑机行业的高档品牌,希望大家在使用注塑机时做好安全措施。

1.注塑机操作前,检查电器控制箱内是否有水、油等杂物进入,若电器受潮,切勿开机。应有维修人员将电器零件擦拭吹干后再开机。

2.注塑机操作前,检查供电电压是否符合,一般不应超过±6%,这一项问题都不会很大。

3.检查急停开关,前后注安全门是否能正常关闭。验证电动机与油泵的转动方向是否一致。

4.检查各冷却管道是否长途畅通,并对油冷却器和机筒端部的冷却水套通入冷却水。

5.DKM注塑机操作前,检查各个活动部位是否有润滑油,并加足润滑油。

6.打开电热,对机筒各段进行加热。当各段温度达到要求时,再保温一段时间,以使机器温度趋于稳定。保温时间根据不同设备和塑料原料的要求而有所不同。

7.在料斗内加足塑料颗粒。根据注塑不同塑料的要求,有些原料如ABS/PC等最好先经过干燥,不然产品容易产生银丝花纹等。

8.要盖好机筒上的隔热罩,这样可以节约电能,又可以延长电热圈和电流接触器的寿命。

操作过程的检查:

1.不要为贪图方便,随意取消安全门的作用。

2.注意观察压力油的温度,油温不要超出规定的范围。液压油的理想工作温度应保持在45-50℃之间,一般在35-60℃范围内比较合适。

3.注意调整各行程开关,避免机器在动作时产生撞击。

工作结束后的清理:

1.DKM注塑机操作完毕后,应将机筒内的塑料清理干净,预防剩料氧化或长期受热分解。

2.应将模具打开,使肘杆机构时间处于闭锁状态。

3.车间必须备有起吊设备。装拆模具时应十分小心,以确保生产安全。

有更多注塑机问题可以随时联系我--西诺罗健 EMAIL:3191@SINOGROUPE.COM

超效节能

再同等工作状态侠,相较传统液压注塑机能实现30%-70%的节能率。德库玛伺服电液系统采用转动惯量较小的细长型电机设计,配合以最先进的高速DSP运算器件,实现磁场定向矢量控制策略。系统具备极快的响应速度,部分伺服电机最高转速达到2500转/分,并且从零转速到最高转速的时间仅36毫秒。注塑机的动作如开合模,射台移动、顶针进退等得以明显加快,缩短了注塑机成型周期,提高生产效率。

超精密。

采用精度达4096脉冲/转的高精度选择变压器作为电机转速(流量)反馈部件和高精度压力传感器作为压力反馈部件,并对压力、流量进行双闭环控制,运用给发偶读DSP实现各种控制算法,平均压力误差可达到0.5bar,转速控制的误差为0.1.%,滞环为零。因此。制品重量重复精度高,满足了生产高精度产品的需要。

超成型稳定性

伺服驱动系统,闭环控制,相较传统液压注塑机,成型重复精度大幅提高

超灵敏相应性

灵敏伺服驱动系统响应迅速,快速启动时间仅需0.05s

超可靠保压性能

相较传统液压注塑机,保压时间调整范围更宽泛,保压性能更稳定。

超恒定油温

伺服电机比例输出液压油,避免多余热量产生。升温慢。液压油甚至不需要哦冷却,实现大幅节水。

金工:15988919623

QQ:2739399772

mail:xiaoshou006@sinogroupe.com

模内贴标技术(In Mould Labeling IML)诞生于欧洲,特点是没有剥离层并且一次成型。在成型中标签与主体材料直接成为一体,嵌在容器外壁。标签材料以薄膜类、塑料材料类为主,不仅会使得用于模内贴标的标签更精美,还提高了标签的耐磨性、耐高温性、防水防潮等。

模内贴标是一项复杂的工艺,它需要注塑机、模具、自动化(机械手)以及标签四个方面具有良好的相互配合,才能保障顺利完成模内贴标的整个工艺过程。模内贴标的技术难点在于模具的结构、标签的品质、机械手的精度、注塑机的开模定位精度、原料与标签收缩性的配合以及标签静电吸附能力。

一、模内贴标成型方式

模内贴标有两种贴标成型方式:吹塑成型和注塑成型。

.吹塑成型工艺

由挤出机挤出的圆柱形中空塑料熔体,逐渐下坠后进入模具内,同时机械手臂(即模具内侧的吸盘)将标签送到模具内壁固定,模具把熔体的圆柱形材料夹住,空气注入使容器膨胀成型,待压力释放后,树脂材料即可加工成模具的形状。吹塑成型的容器大多数用来装液体,包括洗涤剂、果汁和个人护理用品。

.注塑成型工艺

先将标签贴附在模具的阴模内壁上,让阴阳模合紧,将塑料熔体从注嘴注射到模腔内成型。待冷却后,盒体从模具中即可分离。欧洲80%的模内贴标是通过注塑成型的。注塑成型产品多用于各种乳制品包装,如冰淇淋、调味品等。这些产品在欧洲被认为是高档产品,所以能够承担成本稍高的模内标签。

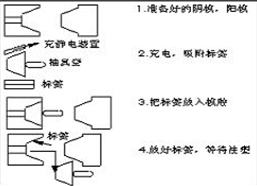

用于吹塑成型标签和注塑成型标签各有其特点。一般来说,吹塑成型用的标签挺度比较高,其材料的背面有压纹或磨砂表面,以利于标签吹塑成型时排出标签与瓶体间的空气。注塑成型用的标签由于注塑时需要的压力大,因此不需材料背面的压纹或磨砂表面便可排出标签与瓶体间的空气。吹塑成型用的标签在模具中一般采用真空吸标工艺,而注塑成型用的标签在模具中一般采用静电吸标工艺。因为注塑用标签生产时产生的压力很大,如果采用真空吸标工艺,标签将会被击穿,射出来的塑胶将堵塞真孔,从而影响生产的连续性。静电模内标签贴标的工序如下图所示。

订制生产线热线:0576-81106961/18758668870

随着低碳时代的到来,节能环保已经成为各行业倡导的主题。

注塑行业正面临着一个飞速发展的机遇,然而在注塑产品的成本的构成中,电费占了相当的比例,依据注塑机设备工艺的需求,传统的注塑机油泵马达耗电占整个设备耗电量比例高达80%~90%。随着能源问题日益受到重视,尤其是我国近些时候循环经济理念的提出,节约能源变得越来越重要,设计与制造新一代“节能型”注塑机,就成为迫切需要关注和解决的问题。

自从发明了注塑机后,注塑机经历过几个技术性的革命。

往复螺杆是早期的一个创新,将塑化及注射功能组合起来,降低了注塑机的成本。

第二个创新算是比例压力及流量阀,这与第三个创新:微处理器的广泛使用息息相关。动作的压力及流量再不用在阀上手调设置,注塑参数还能记忆起来,方便下次调出来再用。

第四个创新是变量泵的广泛采用,这与不断上涨的电费不无关系。

第五个创新应算是全电机的推出。由于没有油温的影响,它将稳定性大幅提高。精准、并行动作、省电、减少噪音、没有漏油污染等都得以大幅改进。

第六个创新便是伺服电机驱动油泵在注塑机上的应用。节能及3/4闭环、减少噪音等的优点近乎全电机的,但成本就低多了。在原油价不断上升的今天,相信会大行其道。

首先我们简单了解一下伺服电机的工作原理

伺服电机是一个典型闭环反馈系统,减速齿轮组由电机驱动,其终端(输出端)带动一个线性的比例电位器作位置检测,该电位器把转角坐标转换为一比例电压反馈给控制线路板,控制线路板将其与输入的控制脉冲信号比较,产生纠正脉冲,并驱动电机正向或反向地转动,使齿轮组的输出位置与期望值相符,令纠正脉冲趋于为0,从而达到使伺服电机精确定位的目的。

联系电话:18758668870

联系人:德库玛小叶