Plastic Crate Injection Molding Line Solution

Help Expend Your Plastic Crate Manufacturing in the shortest time - 30 days!

The input-output ratio will be greatly improved: the most efficient DKM plastic crate injection molding line solution can be provided in the shortest time – 30 days to help customers who are planning to make plant expansion for their plastic crates manufacturing! There are 100% new plastic crate mould popular among market ready for delivery. Kindly check the plastic crates specifications corresponding to ready plastic crate mould as below, if any of them is your demand, welcome to contact us for inquiry.

Amazing?! How could it be available? Check the following information to find why we could provide the efficient crate molding lines in the shortest time 30 days. The core abilities are expert crate molding solutions and strong production capacity.

Check it from the following three aspects:

Nowadays, plastic crates are optimized to be used for various applications, such as logistic solution, retail logistics (storage and order picking), food industry, agricultural industry (transportation and storage of fruit and vegetables), poultry transport, and other general Industries.

And we know well about the performance requirement of different plastic crates thanks to Brother Company Sino Mould co., ltd., usually, customers pay more attention on crate weight, sink mark, strength, stacking ability…We could help customers increase the competitiveness by improving the plastic crates to be better ones. Such as:

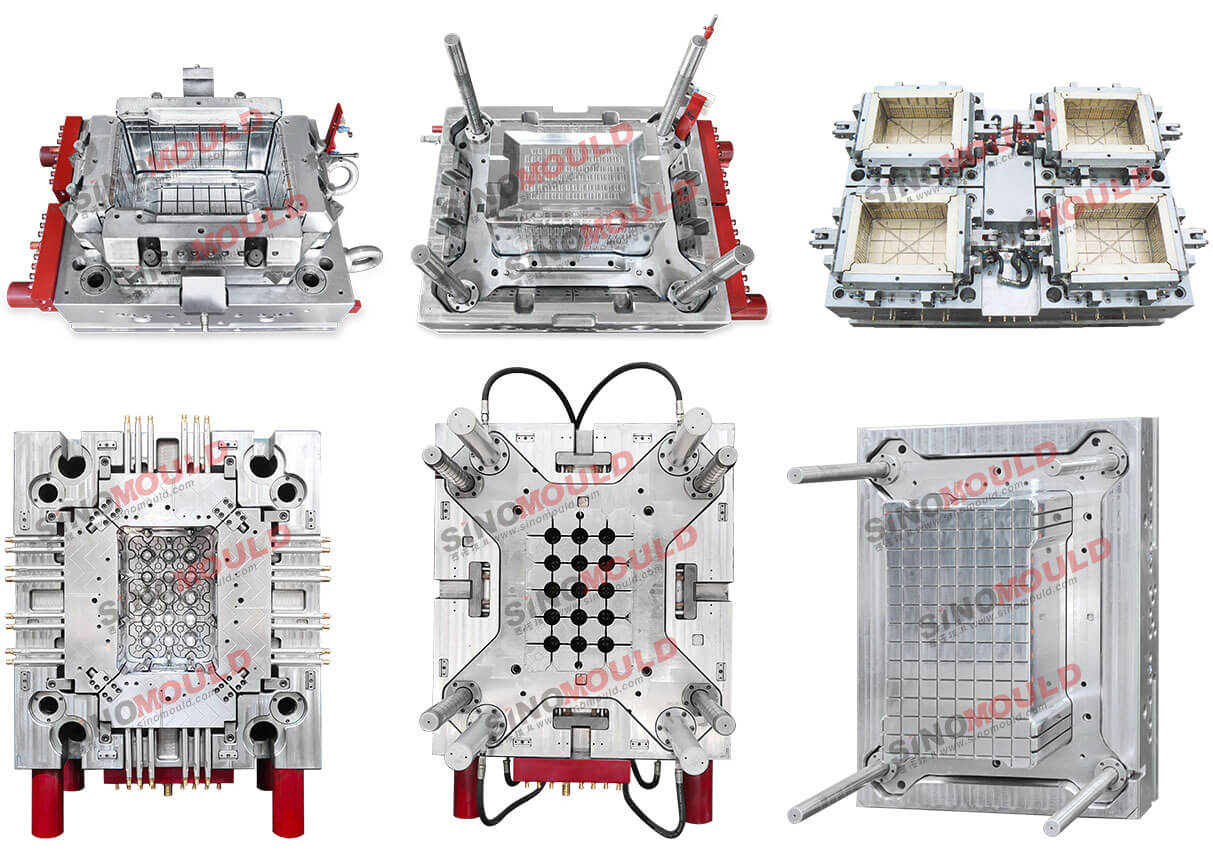

Regarding the general plastic crate mould, under the best tooling condition, the key technical points to guarantee the final superior crate production are mould steel, injection system, cooling system and ejector system.

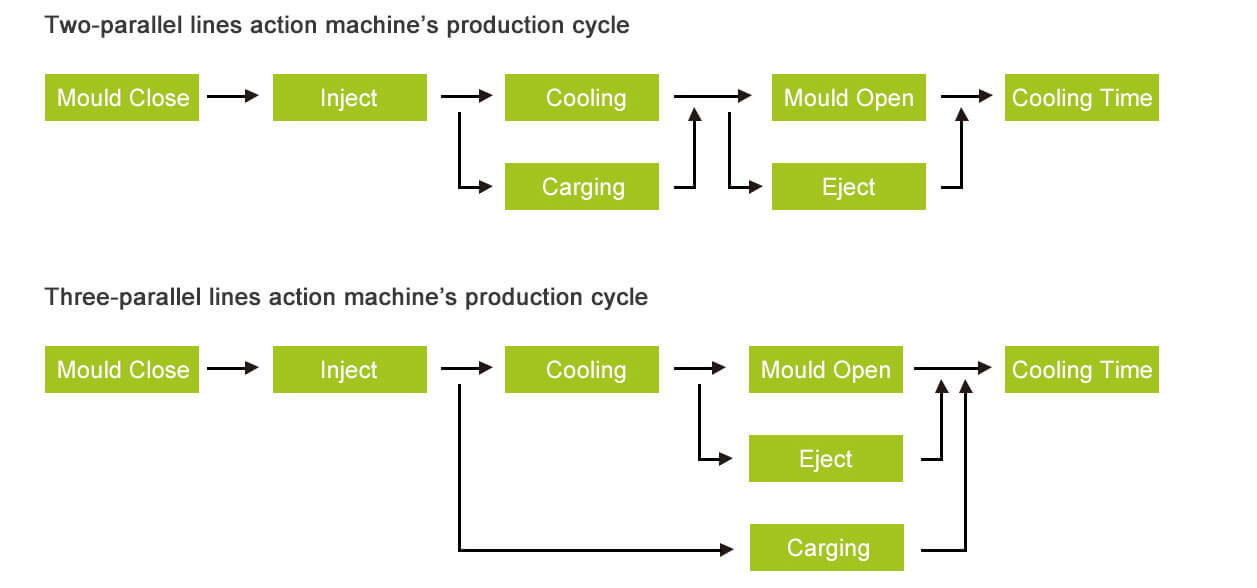

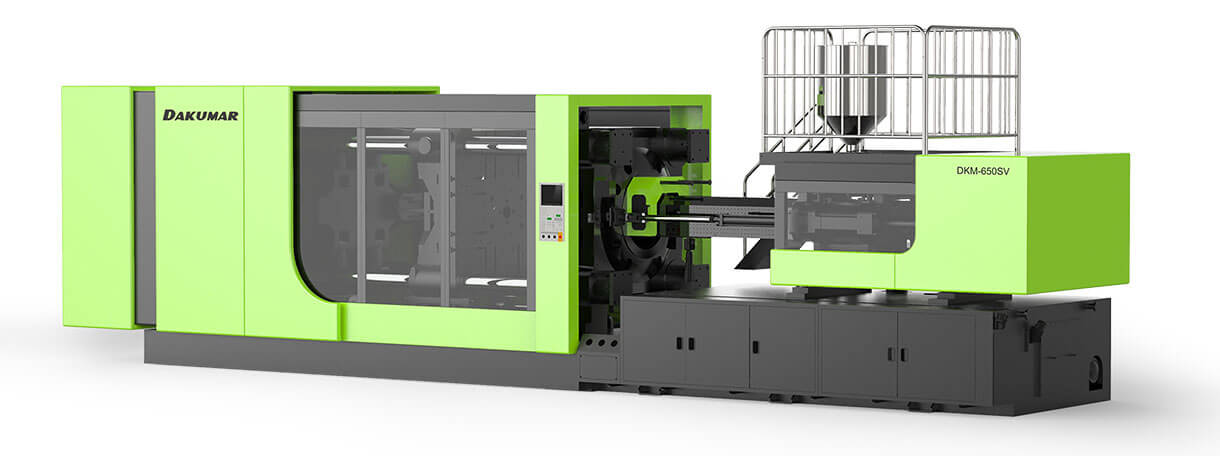

Generally, the normal plastic injection moulding machines could be used for plastic crates production, but, it could help customers manufacturing the plastic crates more efficiently if the machines have the following highlights, that’s what are designed in the DKM plastic injection moulding machines dedicated to better crate molding solution.

Notice: Notice: if you are buying the crate mould and machines from different suppliers, please note that the size of the plastic crate mould usually would be bigger because of the sliders structure, please pay attention on the tie bar space when confirming machine model.

It makes DKM different – one stop purchasing and service satisfying your requirements, help customers save much energy and time which could be spent on other important projects.

Looking for reliable manufacturer in China to expand your plastic crate manufacturing business quicker? Contact us now! Start your new plastic crate molding line in the shortest time 30 days. Dedication to complete each process, helping customers start production quicker and keep stable running is the ultimate goal.