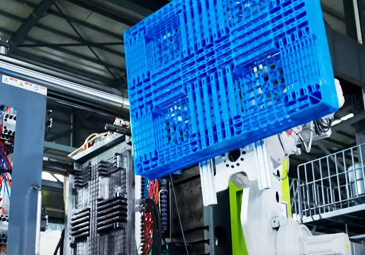

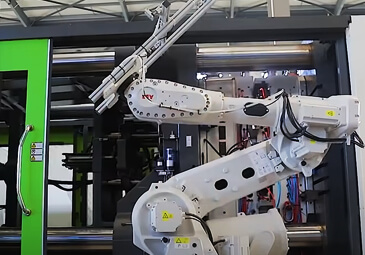

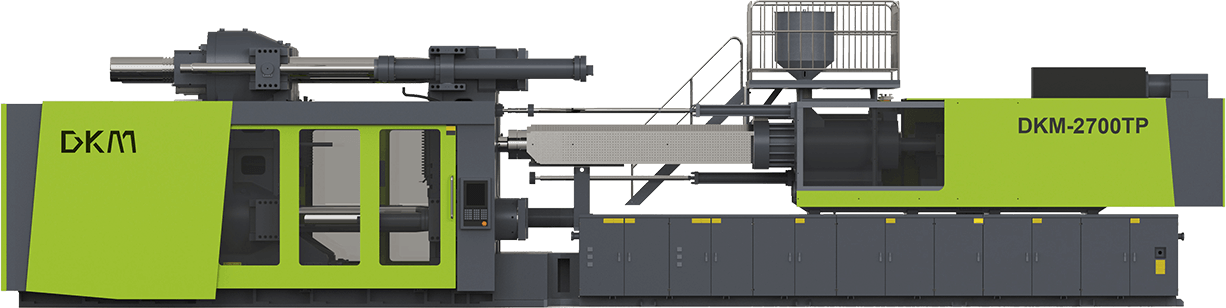

DKM Plastic pallet mould machine line includes DKM-1650, DKM-2250, DKM-2800 injection molding machine, pallet mould(Powered by SinoMould.com), robot(Powered by ABB) and so on.

DKM has realized 69s cycle time for a pallet with 15KG weight, 60days short lead time.

DKM has continuously done below optimizations during the past years.

Continuously increase the quality and decrease the cost.

Continuously shorten the molding cycle time.

Continuously shorten the delivery time of the pallet molding line.

Continuously RND on stability of pallet production.

DKM pallet injection molding line has become the industry leader in all aspects. In order to create greater value for injection molding, we hope that your choice can make you stand out in the pallet production field.

3 axis linkage to shorten cycle times about 30%-50%

3 axis linkage to shorten cycle times about 30%-50%

20%-30% energy saving and higher plasticizing precision by electrical motor

20%-30% energy saving and higher plasticizing precision by electrical motor

Updated with electrical pre plastic charging system and self-locking nozzle

Updated with electrical pre plastic charging system and self-locking nozzle

![]() DKM studies the injection molding process of pallet in combination with SINOMOULD, such as melt plastic flow velocity analysis, temperature analysis and pressure analysis with mold-flow software.

DKM studies the injection molding process of pallet in combination with SINOMOULD, such as melt plastic flow velocity analysis, temperature analysis and pressure analysis with mold-flow software.

![]() DKM studies various formulations of HDPE and PP by our own research institute. This research institute is one of the Polymer Molding Research Center of the China National Academy of Engineering.

DKM studies various formulations of HDPE and PP by our own research institute. This research institute is one of the Polymer Molding Research Center of the China National Academy of Engineering.

![]() Optimal injection & cooling system realize high speed injection, to maximize pallet production efficiency.

Optimal injection & cooling system realize high speed injection, to maximize pallet production efficiency.

Product Material:HDPE

Mold Size: 2200*1600*1500 (mm)

Cycle time: 89s

Description:

The pallet mold is provided by Sino Mould, this size of mould is 2200*1600*1500mm, the total amount reaches 41 Ton. The metal of the moulding area is made of high thermal conductivity material, with the scientific mould design, it ensures the high efficiency production of the mould; the moulding area adopts the inserted splicing structure, which not only ensures the subsequent maintenance and replacement of the inserts, but also facilitates the separate inlet and outlet of the water circuit, and achieves a better cooling effect.

The 22-point Anole hydraulic needle valve ensures a balanced inlet for each moulding area; the mould parts are processed with high precision to ensure that the inlays are intermixed with each other, which is convenient for the user's maintenance.

The cumulative time for this set of pallet moulds is only 83 days from the design, processing, and the T1 trial moulds.

![]() DKM Plastic Pallet Mould Machine Production Line Service Experience.

DKM Plastic Pallet Mould Machine Production Line Service Experience.

![]() DKM has provided more than 60 plastic pallet production lines all over the world and won high praise from users.

DKM has provided more than 60 plastic pallet production lines all over the world and won high praise from users.

![]() DKM has received a lot of comments and suggestions from the sales and after-sales of these production lines, and has made continuous improvement for 9 years.

DKM has received a lot of comments and suggestions from the sales and after-sales of these production lines, and has made continuous improvement for 9 years.

![]() DKM and SinoMould have good experience, technology accumulation and inheritance system for providing top level Pallet Molding Line.

DKM and SinoMould have good experience, technology accumulation and inheritance system for providing top level Pallet Molding Line.

Here are videos of some of our plastic pallet production lines